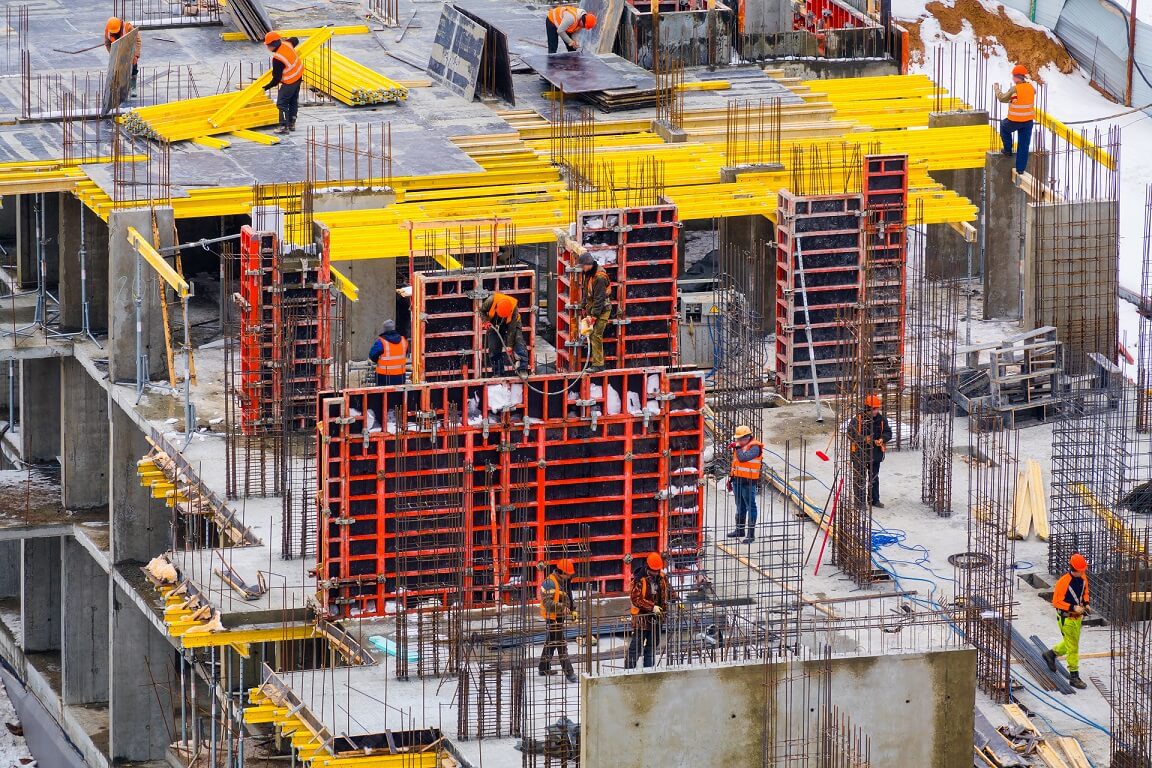

How to accomplish cost savings in formwork construction

The reduction of formwork construction is crucial to reducing the overall cost of the project, as it accounts for up to sixty percent of the total cost of the concrete structure. In this regard, decisions made during the design phase can play a crucial role. New materials, accoutrements, and prefabricated formwork components may allow designers to reach their design objectives at a lower cost.

How to Reduce the Expenses of Formwork Construction?

- Employ a single framing scheme throughout the endeavour. This would enhance the education of laborers and reduce the cost of mobilization and formwork materials. Two framing strategies are only justifiable for large-scale undertakings.

- Use the same depth for all beams and joists because the savings would outweigh the increase in steel and concrete costs. When a beam is severely loaded, its width may be four or five times its depth.

- Even if the masses and spans are different, maintain the same beam outlines and modify the reinforcement ratio to resist the load.

- By uniformly spacing columns to attain uniform sizes for columns, joists, and beams, one can save money by simplifying the process of forming.

- Increase the reusability of forms by utilizing the same column width laterally and vertically in a single stack. Change the concrete’s reinforcement and strength to accommodate pressures.

- Utilizing consistent floor-to-floor height is advised. However, if modification is required, upper-story height should be decreased. It would be less expensive and simpler to reduce column form than to extend it.

- Use small drop panels as opposed to tapered columns in flat plates to reduce the cost of formation. It is recommended to use steel shear heads in lieu of capitals and drop panels if the slab thickness is at least 200 centimetres.

- Adjust the height of drop panels to conform to lumber industry standards.

- To save time and money, orient all framework in a single direction when constructing a one-way system.

- Use standard form specifications for one-way joists and two-way domes to avoid fabrication charges for special forms.

- Maximize the capacity of minimum-sized members by arranging the sizes and spacing of forming members. minimal thickness slabs governed by fire ratings must span at least as far as the minimal reinforcement will allow. Minimum thickness and reinforcement walls can simultaneously support column loads, function as grade beams or transfer girders, resist lateral loads, and serve as petitions or exterior walls.

- Consider using flat plate for spans up to 7.6m because its forming system is the cheapest, quickest, and shallowest in comparison.

- Tight tolerances increase labour costs and labour hours. Therefore, allow reasonable tolerances and only specify strict tolerances where they are required.

- Determine when to eliminate forms. Use a strength requirement for timbers and slabs and a time limit for walls and columns. To prevent excessive deflection, you should consider requiring reshoring until the design strength has been achieved.

Disclaimer: This content is provided solely for your review. Erusu Consultants takes no liability for this article. The reader is advised to form their own opinion. Please consult a structural engineer before making any final decisions.